Please enable the breadcrumb option to use this shortcode!

Surface treatment

After production many parts have to be treated to preserve or embellish them. Outsourcing the most common surface treatments is possible both in Asia (China, India and Pakistan) and Europe (Poland, Turkey and Bosnia). In our own location in Bosnia we have our own blast machine and powder coating installation. In our own powder coating installation we can lacquer parts to a length of 4,000mm, a width of 2,500mm and a height of 2,500mm.

Doing surface treatment ourselves allows us to keep our process competitive and reduce the risk of damage to a minimum.An enumeration of the possibilities:

Doing surface treatment ourselves allows us to keep our process competitive and reduce the risk of damage to a minimum.An enumeration of the possibilities:

- • Paint spraying, one or more layered paint systems.

• Powder coating / Powder lacquering (info powder coating / powder lacquering).

• Sandblasting of steel (info sandblasting).

• Glass bead blasting of stainless steel (info glass bead blasting).

• Thermal galvanizing (info thermal galvanizing).

• Duplex system, a combination of a thermally galvanized sub-layer and a top-layer of one or more powder coated layers.

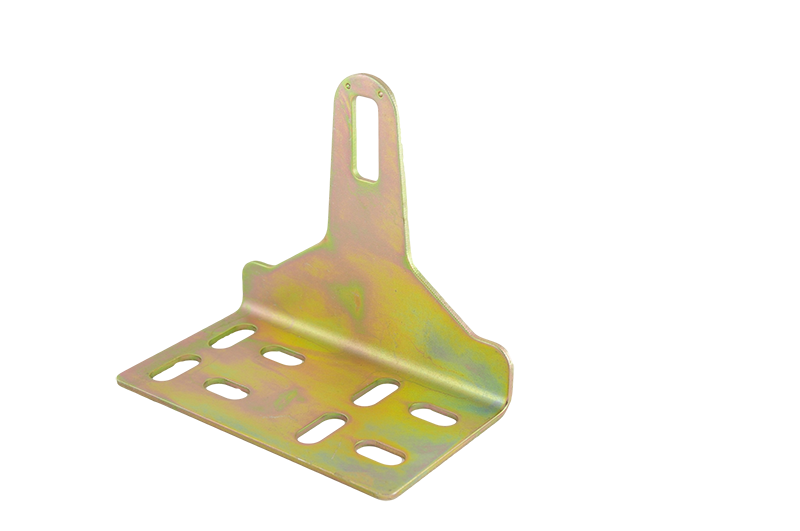

- • Electrolytic galvanizing (info electrolytic galvanizing).

• Passivation in yellow, blue and black in combination with electrolytic galvanisation (info passivation).

• Nickel plating (info nickel plating).

• Chrome plating (info chrome plating).

• Anodising of aluminium, in colour if desired (info anodising).

• Polishing, both mechanic polishing and electrolytic polishing (info polishing).

• Grinding, provided with a grain structure if desired (info grinding).

We will gladly advise you on which surface treatment best suits your product. Good packaging of the parts is crucial after the surface treatment, in order to receive a damage-free product on arrival. For many clients we make customised packaging, provided with an article number, logo, etc, if desired.- • Electrolytic galvanizing (info electrolytic galvanizing).

Products

TOS outsourcing; your partner for machining (conventional and CNC turning and milling work), welding, forging, casting (metal and synthetic materials), extrusion, recasting, separating, preserving and assembling.