Please enable the breadcrumb option to use this shortcode!

Extrusion

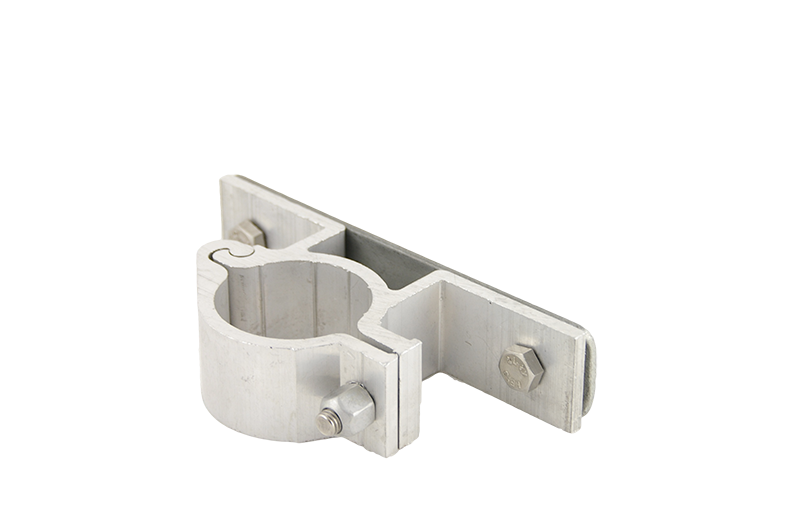

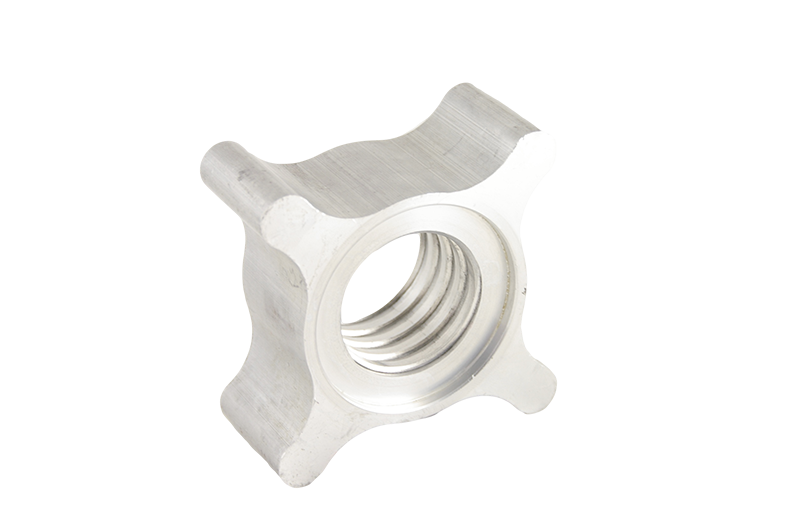

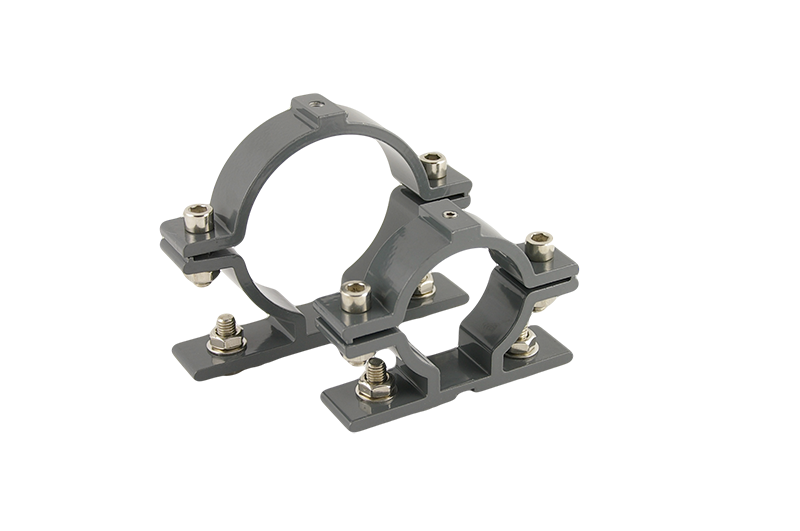

For several clients in the Netherlands and Belgium we outsource aluminium extrusion profiles, sometimes only sawn to the proper length and in other cases welded or processed. Our extensive network of European (Bosnia, Poland and Turkey) and Asian suppliers (China and India) includes several extrusion companies. Depending on the product’s size, the factory’s location and the desired finishing and surface treatment we look for an appropriate supplier.

Thanks to our experience in the field of extrusion we can give advice on the design, purchase, alloy, finishing and surface treatment of your extrusion profile. In aluminium profiles smart, cost-efficient solutions can often be devised, reducing costs of, for instance, assembly.

Extrusion of aluminium is done with a special extrusion press; this press pushes a billet (a length of aluminium) through a matrix. The holes in the matrix produce the

proper aluminium profile. After extrusion the profile is cooled down, stretched, sawn to the right length and stress-relieved. After extrusion of the profile the options are to anodise or powder coat the aluminium. Beside that many profiles require machining operations (machining), which is often possible. If the profiles are part of an assembly, many of our suppliers are capable of carrying out assembly work. As aluminium tends to scratch, it is important to pack it up the right way.

Extrusion can be done in the most common aluminium alloys, such as AL 6060 / AL 6061 / AL 6063 and AL 6082; depending on the application we can advise you on which aluminium alloy to use.

Products

TOS outsourcing; your partner for machining (conventional and CNC turning and milling work), welding, forging, casting (metal and synthetic materials), extrusion, recasting, separating, preserving and assembling.